Struct-Fast® Product:

Hollo-Bolt

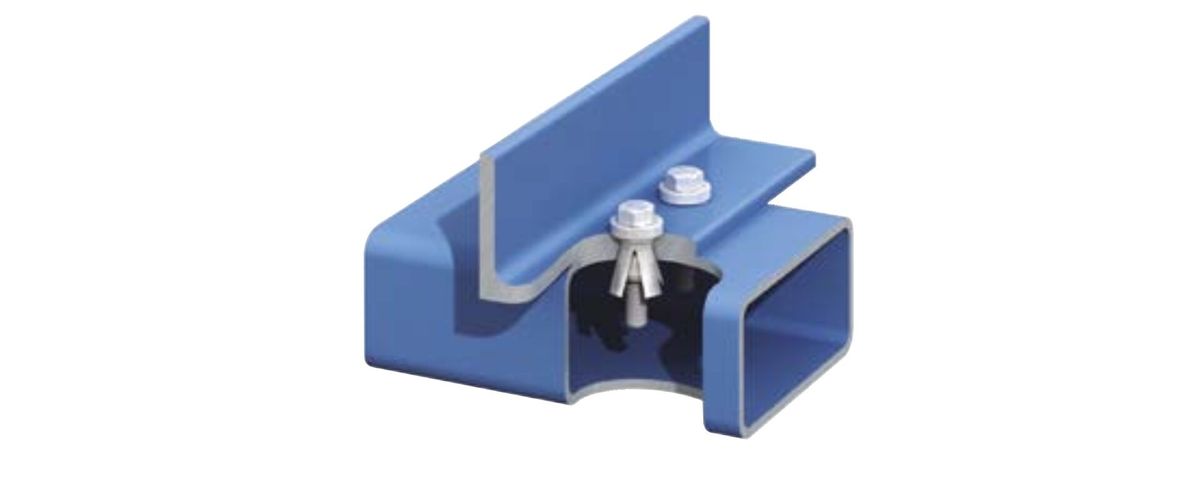

For fastening where access is available from one side only. Suitable for hollow sections or steelwork.

Hollo-Bolt

For fastening where access is available from one side only. Suitable for hollow sections or steelwork.

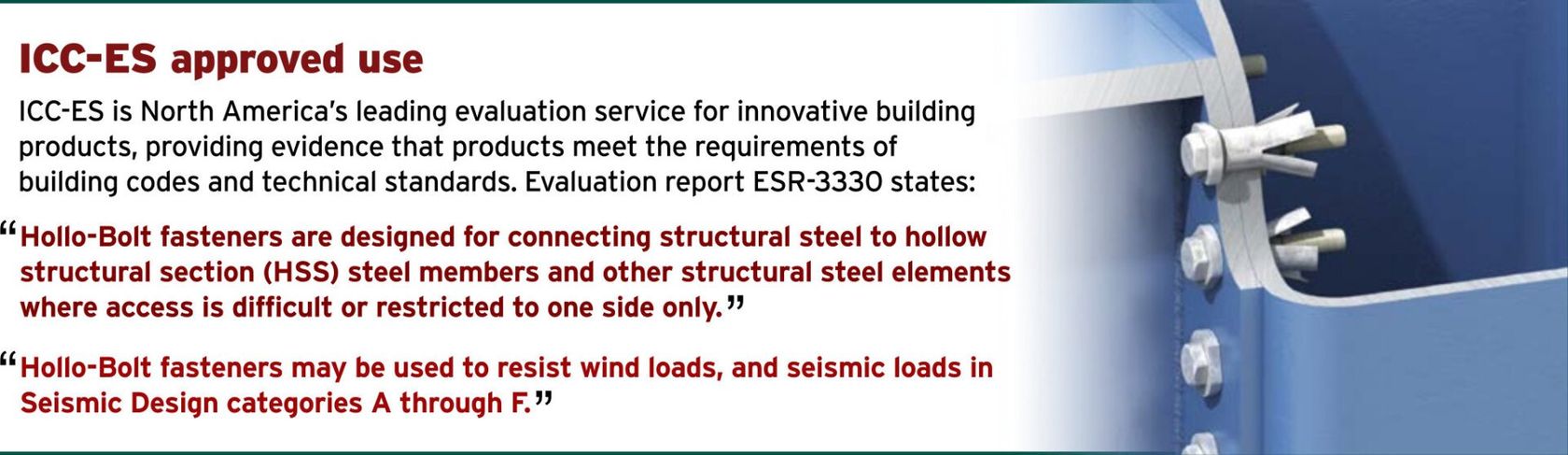

Hollo-Bolt (Hot Dip Galvanized) is approved for use in all Seismic Design Categories (A throughF) and is compliant with the International Building Code. Extracts of ICC Evaluation Service Report ESR-3330 can be found below.

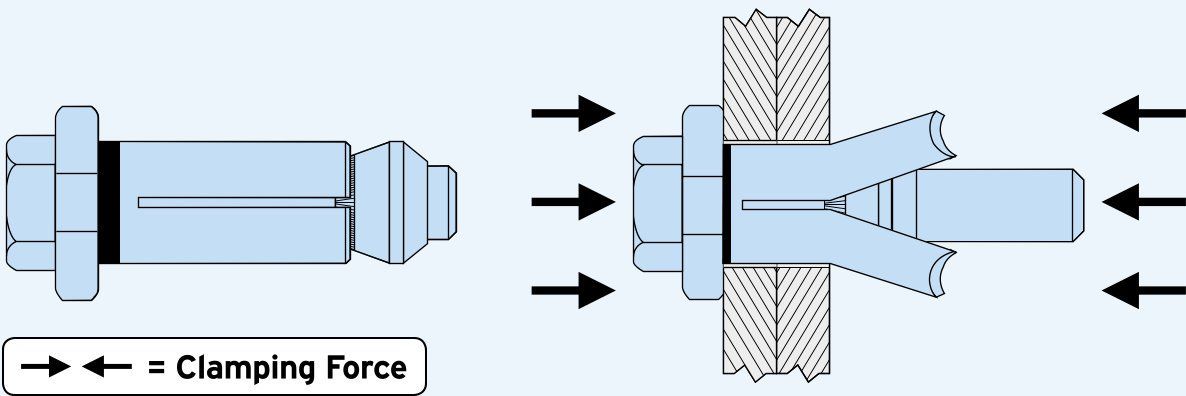

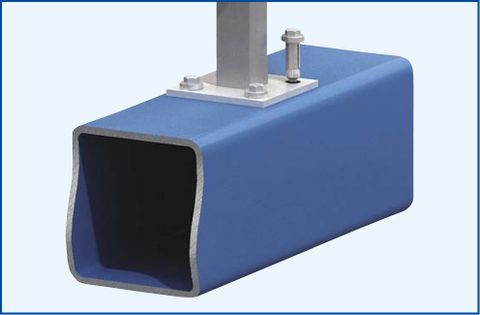

The Connection Concept

A typical connection is made by inserting the Hollo-Bolt into the pre-drilled holes of the fixture and hollow section. As the bolt head is tightened, the cone is pulled up the bolt thread, causing the sleeve to expand until the cone locks the sleeve against the hollow section’s inner wall.

At full tightening torque, a clamping force is established between the fixture and the steel section to form a secure connection. Once installed, only the head and the collar are visible.

LRFD design strength & ASD allowable strength

LRFD design and ASD allowable strengths (taken from ESR 3330) are to be used only when designing a bolted connection to AISC 360, AISC 341 and AISI S-100 as referenced in Section 2205 of the IBC.

Hollo-Bolts can be used on a variety of steel hollow sections and shapes. Limit States of the section, could occur at a lower figure and therefore its strength should be checked by a qualified Structural Engineer.

Refer to ESR-3330 and confirm with Struct-Fast for details of connection design, installation and conditions of use.

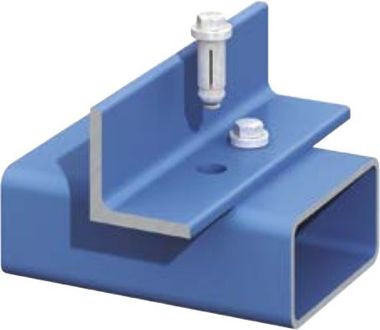

Hollo-Bolt Installation

Step 1

Align pre-drilled fixture and section then insert the Hollo-Bolt (a). (Figure 1)

Step 2

Grip Hollo-Bolt collar with an open ended wrench. (Figure 2)

Step 3

Using a calibrated torque wrench, tighten the central bolt to the recommended torque (b).(Figure 3)

Notes:

a) Before tightening, ensure that the materials that are to be connected together are touching. See table above for tightening torque.

b)Power tools, such as an impact wrench, may be used to speed up the tightening of the Hollo-Bolt. However, when using power tools, always complete the tightening process with a calibrated torque wrench to ensure the correct torque is applied to the Hollo-Bolt.

MENU

GET IN TOUCH

Phone: 800-327-6719

Fax: 410-770-9414

hugh@structfast.com

8648 Commerce Drive

Suite 1200

Easton, MD 21601

STAY CONNECTED

Join our newsletter and find out more.

Contact Us

We will get back to you as soon as possible

Please try again later

Struct-Fast is a registered ® trademark. All content within this website is ©2021

Site design: MarketingHouse ©2021